Incremental Rotary Encoders

High-Precision Solutions for Every Industry

Hohner Automation combines over 40 years of expertise in the design and manufacture of rotary incremental encoders to deliver precision solutions for the most demanding applications. Whether you need standard models or highly customized encoders, our product range meets the technical and operational challenges of industries worldwide — including India, one of our fastest-growing markets.

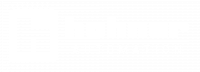

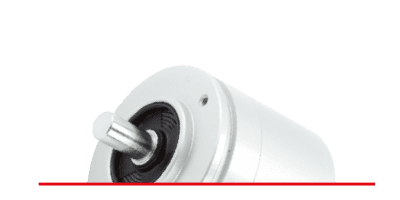

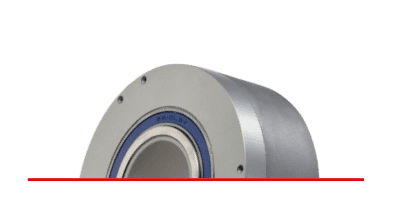

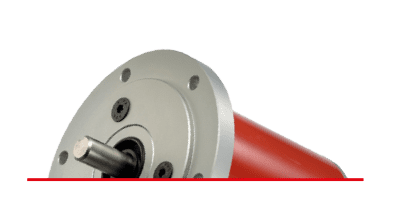

Miniature Incremental Encoders

- External diameter from Ø 24 mm

- Solid and hollow shaft from Ø 4 - 12 mm

- Up to 10,000 ppr

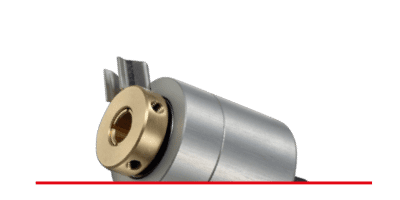

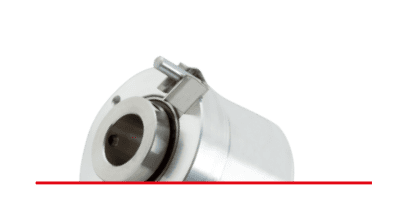

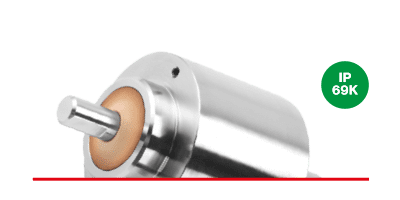

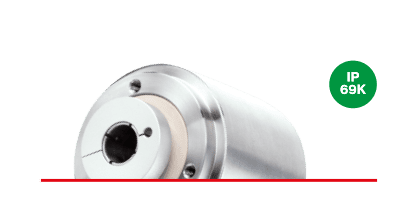

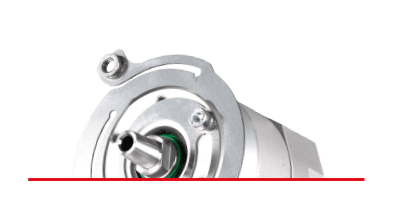

standard Incremental Encoders

- External diameter Ø 50 - 58 mm

- Solid, hollow and conic shaft Ø 6 - 15 mm

- Up to 65,536 ppr

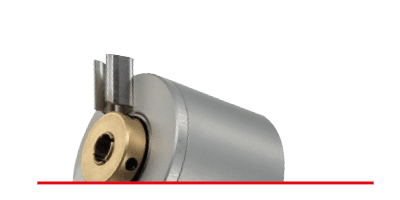

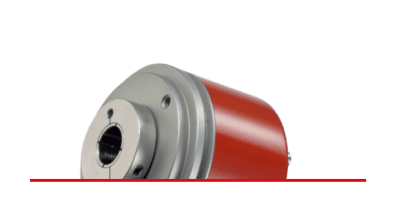

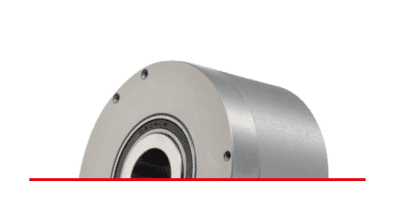

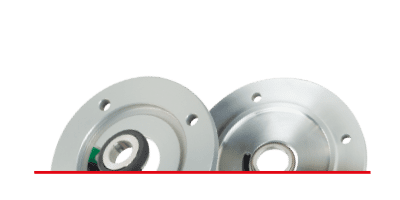

big Shaft Incremental Encoders

- External diameter from Ø 77 mm

- Solid and hollow shaft Ø 12 - 65 mm

- Up to 50,000 ppr

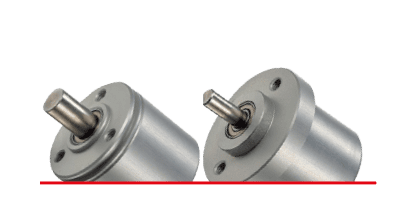

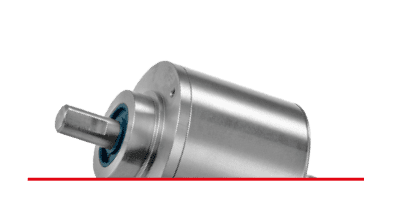

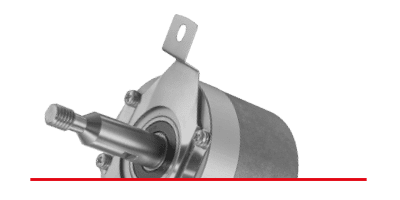

Kit Incremental Encoders

- Compact design

- Great mechanical robustness

- Hall effect magnetic technology

What Is a Rotary Incremental Encoder?

A rotary incremental encoder is a position sensor that generates a series of pulses corresponding to incremental angular displacements of a rotating shaft. Each pulse represents a fixed increment of rotation, allowing precise calculation of:

- Speed

- Position

- Direction

- Length (in motion systems)

Unlike absolute encoders, incremental encoders do not retain position data when powered off, but their simplicity, versatility, and precision make them the most widely used option in industrial automation, robotics, medical equipment, and subsea applications.

In India’s fast-expanding automation sector, rotary incremental encoders play a key role in factories, processing plants, and equipment manufacturing.

Working Principle of Incremental Encoders

Incremental encoders typically use either optical or magnetic sensing technology:

- Optical incremental encoders work by shining light through a precisely patterned disc, generating digital pulses as the disc rotates. They offer extremely high resolutions — up to 65,536 pulses per revolution (PPR) — making them ideal for high-precision tasks.

- Magnetic incremental encoders use magnetic fields to detect position changes. These are highly robust against dust, humidity, vibrations, and extreme temperatures, making them perfect for harsh environments such as subsea installations or heavy industrial machinery.

Our product line at Hohner Automation includes both technologies, allowing us to serve diverse industries with specific environmental and performance requirements.

The generated pulses can be interpreted by control systems to measure:

- Speed: RPM (Revolutions per Minute)

- Position: By counting pulses from a reference point

- Direction: Using quadrature output signals (A, B channels)

This versatility makes incremental encoders the backbone of modern motion control systems.

Key Features and Specifications

At Hohner Automation, we offer an incredibly wide range of incremental encoder specifications to fit virtually any application:

- Diameters: From Ø 36.5 mm to Ø 160 mm

- Resolutions: From 1 to 65,536 pulses per turn (PPR)

- Shaft Diameters: From Ø 4 mm to Ø 42 mm (solid shaft, blind hollow shaft, hollow shaft, conic shaft)

- Temperature Range: –40°C to +115°C

- Technology: Optical, magnetic or inductive sensing

- Housing Materials: Stainless steel, aluminum, or plastic

- Output Types: TTL, HTL, Open Collector, RS422

- Mounting Options: Flange, servo, clamp, or customized mounts

- Ingress Protection (IP): Up to IP69K for demanding environments

These options allow full integration into automation lines, robotic arms, conveyors, medical devices, and even underwater vehicles that require pressure resistance up to 100 bar.

Why choose Hohner Automation?

We don't just sell encoders — we engineer long-term solutions alongside our clients.

Frequently Asked Questions (FAQ)

Q1: What is the difference between rotary and incremental encoders?

Rotary encoders can be incremental or absolute. Incremental encoders generate pulses that must be counted from a reference point, while absolute encoders give an exact position reading at any time.

Q2: What resolution do I need for my application?

Q3: Do you offer customized incremental encoders?

Yes, Hohner Automation specializes in encoder customization. We can adapt mechanical, electrical, and connectivity aspects based on your specifications.

Q4: What industries use incremental encoders?

Incremental encoders are used in automation, robotics, medical equipment, printing, packaging, elevators, oil & gas, and many other industries.

Q5: Do you offer local support in India?

Yes, we offer local support in India through our partner Multidimensions, who provide technical assistance and ensure fast delivery.

Contact Hohner for Your Incremental Encoder Needs

We’re ready to support your industrial projects in India and worldwide.