Absolute Rotary Encoders

Engineered for India’s Rapid-Growth Industries

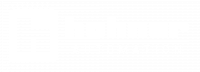

At Hohner Automation we design and manufacture absolute rotary encoders that retain their exact angle the moment power is restored. From robust SSI/BiSS devices to sub-millisecond EtherCAT and PROFINET solutions, our portfolio covers every major industrial protocol, as well as classic 4–20 mA analog and parallel-word formats. Each unit is engineered, assembled and 100 % tested in-house to deliver dependable position feedback right out of the box—no homing cycles, no lost counts, no downtime.

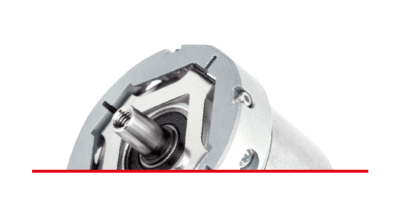

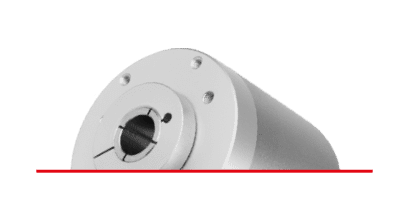

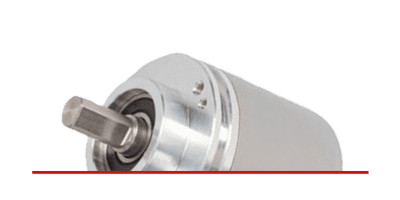

SSI / biSS Encoders

- Up to 21-bit single-turn, 24-bit multi-turn

- Real-time synchronous data

- Industry-standard connectors

Sin/Cos Encoders

- Absolute and incremental encoders

- Absolute resolution 1 sin/cos per turn

- Incremental resolution 2048 sin/cos per turn

Analog Encoders

- 0–10 V / 4–20 mA

- Configurable by buttons / cable

- Limit Switch function

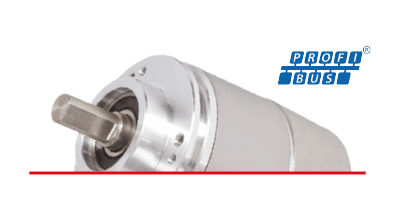

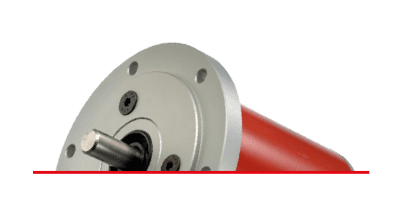

Fieldbus & Industrial Ethernet Encoders

- PROFIBUS, CANopen, DeviceNet

- PROFINET, EtherCAT, Ethernet/IP

- Up to 16-bit single-turn, 14-bit multi-turn

Parallel Encoders

- Up to 13-bit single-turn, 25-bit multi-turn

- Hard real-time without CPUs

- Still popular in steel mills

Single-turn absolute encoders measure position in reference to a 360-degree turn. When the shaft exceeds 360°, the position of the following turns will be like the first. If you need to track revolutions as well, step up to our multi-turn versions; at Hohner we have a wide range of multi-turn absolute encoders at your disposal with all the interfaces above.

How an Absolute Rotary Encoder Works: Inside the Technology

Absolute rotary encoders create a unique digital word for every shaft angle. A disc split into concentric Gray-coded tracks—read optically, magnetically, or capacitively—spins with the shaft. A sensor array captures all tracks at once and outputs the word, so the PLC knows the exact position from the very first microsecond, even after a power cut.

By eliminating homing routines and incremental drift, absolute rotary encoders slash start-up time and unplanned stops on Indian automotive lines, steel mills, and textile plants. The position data flows straight to the controller over SSI, BiSS, CANopen, or industrial Ethernet, ensuring precise, traceable motion control at every stage of production.

Single-Turn vs Multi-Turn: Which One Fits Your Application?

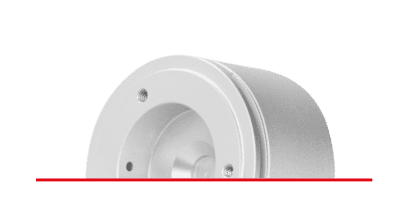

A single-turn absolute rotary encoder reports the exact angle within one 360-degree revolution—ideal for bottle-capping stations, cam indexers, or pick-and-place robots where the shaft never exceeds a full turn. When the axis can spin indefinitely—think jet bridges, solar trackers, or overhead cranes in India’s ports—you need a multi-turn absolute rotary encoder. Hohner counts each complete revolution with either:

a long-life lithium battery that maintains the turn counter for years without external power, or

an energy-harvesting Wiegand sensor that flips polarity once per turn and powers a non-volatile counter—no gears, no maintenance.

Both options guarantee that your PLC wakes up knowing the true position and total turns, eliminating homing cycles and downtime in mission-critical applications.

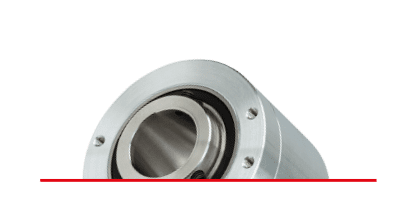

Optical vs Magnetic: Choosing the Right Sensing Principle

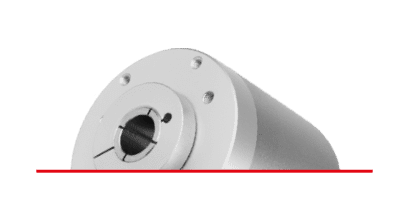

In clean, controlled environments—CNC machining centres, high-speed pick-and-place lines, pharmaceutical fillers—optical absolute rotary encoders deliver the sharpest signal quality. A precision-etched code disc and LED–photodiode array produce crisp, noise-free position data that lets your PLC hold tight tolerances shift after shift. The only caveat: keep the encoder in at least an IP 64 housing or above so that oil mist and dust don’t scatter the light path.

When shock, vibration, or airborne grit are part of daily life—steel mills in Odisha, bulk-handling conveyors on the west-coast ports, wind turbines in Rajasthan—magnetic absolute rotary encoders prove their worth. A diametrically magnetised rotor and Hall or magneto-resistive sensors shrug off contaminants, broad temperature swings, and axial loads, ensuring reliable feedback with virtually zero maintenance.

As a rule of thumb: choose optical for maximum measurement fidelity in clean settings and magnetic for durability in harsh Indian industrial climates. If you’re still unsure which technology best protects uptime on your line, our Hohner India team can help tailor the ideal absolute rotary encoder for your application.

Key Specs that Matter in India

- Resolution. Domestic packaging lines often run 200 mm pitch belts at 300 cycles/min. A 16-bit single-turn gives 65 536 counts, translating to 0.0055 mm linear granularity—overkill but future-proof. For basic flap-folders, 12 bits do fine.

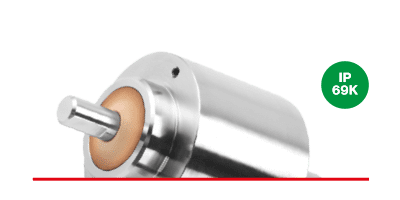

- Ingress protection. Between monsoon splash and coal dust, IP 67 should be your default for outdoor use.

- Temperature. North Indian furnaces hit 70 °C ambient. Check the data-sheet, not marketing copy. Magnetic heads tolerate 105 °C; optical rarely goes above 85 °C.

- Shock & vibration. Indian rail-tamper machines deliver 100 g shocks. Go magnetic (no glass disc) and specify M12 radial connectors with clamp-style strain relief.

- Finally, consider cable length. SSI/BiSS handle 400 m at 100 kHz with shielded twisted pair; PROFINET needs Cat-5e but piggybacks on your existing Ethernet switches.

By matching these specs early you prevent frantic midnight calls when a line stops and the OEM is 7 000 km away.

Frequently Asked Questions (FAQ)

Q1:Can I mix SSI and incremental signals?

Yes—order the dual-output option; our E58-SSI-AQ delivers 25-bit SSI plus 1 024 ppr quadrature.

Q2: What if power fails mid-turn?

The absolute code disc stores angle mechanically; multi-turns capture revolutions too.

Q3: How far can I run PROFIBUS cable?

100 m per segment at 12 Mbaud with proper RS-485 stubs; use repeaters beyond that.

Q4: Do I need to home the axis at start-up?

No. Because an absolute rotary encoder reports its exact position immediately on power-up, the PLC can skip the homing cycle—saving seconds on every machine restart and avoiding crashes if limit switches have shifted.

Q5: How long does the battery last in a battery-backed multi-turn encoder?

Our high performance lithium batteries typically sustains the multi-turn counter for 10 + years at 25 °C without external power, , so you won’t need to worry about replacements during normal equipment life.

Contact Hohner for Your Incremental Encoder Needs

We’re ready to support your industrial projects in India and worldwide.